ok i got some new switches to replace my old switches in my mas stick. i wanna use quick disconnects because i heard they were the easiest to deal with and im not to fond of soldering. im new to this and i just wanted to know if anyone could give me some advice on what steps i should take. a pic should be below. thanx in advance

http://www.arcadestickmonk.com/SFACmod.html

This is for the SFAC stick but its basically the same thing. Judging by how short the ground wire is between the buttons though you will probably need to rewire that and do a daisy chain. But just follow the steps in the link. Strip the old wiring and crimp on disconnects then stick them on to the new microswitches. Just go the RadioShack and get some .187 disconnects, a wire crimper, and some 18-22 gauge wire.

damn, double post. ok, cool i’ll check it out and see wassup

are those the new switches? or have you yet to install them.

youll need wire 18-22 gauge

wire crimpers

and .187 Quick disconnects

soldering iron

put the soldering iron on the pin untill the solder is hot and you can pull the wire off (not tug it off just move it off)

crimp the wire into the QD’s (looks like you wanna use new wire for the daisy chained ground since the wires seem kinda short)

then take out the buttons and put the new switches on

and finally slide the QD’s on to the new switches

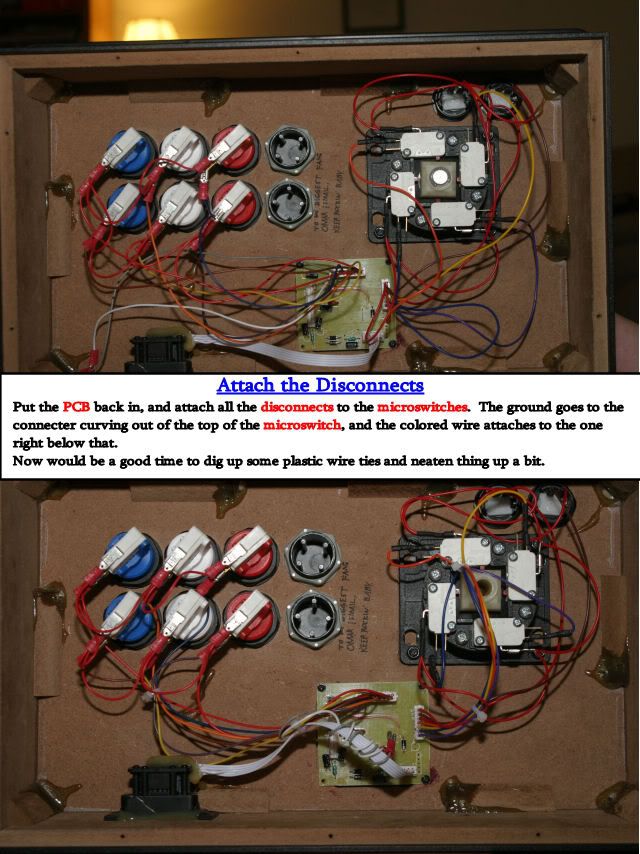

examples of a happ qd’d

http://i44.photobucket.com/albums/f38/Bountyhunterinic/inside2.jpg

http://xs307.xs.to/xs307/06416/wiring.jpg

ps do not dewire anything off that little black thing or your p360

pps whats wrong with your current switches?

also double threads is a no-no

Is that really what the wiring inside of a MAS is like?

I’m digging the scotch tape.

i have yet to install them button m4sh. u dont have to solder with new disconnects do you? also, can u just take the wire off the old switches without a soldering iron and replace them since im gonna throw them away anyways?

lol, yea they got me with the scotch tape shit. i opened it up and im like wtf. they replaced my sticks for free when my old sticks got fucked up in hurricane katrina. now i see what a wonderful job they did. HAHAHA

oh yea, i know nothing about this stuff so its gonna take some time to understand what yall are talking about with the ground wire, etc.

well i noticed my stick wasnt responding well when playing mvc2 when i try to dash or fly with sentinel, iron man, or whoever. seems like using 2 button combination attacks just isnt coming out for me. a friend told me i most likely need to change my switches cause they get bad sometimes. now, here i am.

oh god, if that’s what a MAS looks like on the inside…

(Granted, I’m not hip to the idea that GoPodular uses solder on QDs… What’s the point then?!)

its best to use the wire they gave you if your not too good at soldering

you dont have to solder them off you can just cut them (as close to the micro switch as possible

do this

1.)write down what color wire went where

i did it for you

darkblue with black = start

darkblue with black(higher up on the chip) = select

light blue = lp

purple = mp

grey(might have black)= hp

green with black (on right side of chip = lk

grey with black = mk

green with black (on left side of chip = hk

you can change this or whatever but thats how it looks to me judging from the picture

2.)strip and crimp the wires into a QD

as shown here

CRIMPING

3.)pop in new microswitches and plug in accordingly

cool, thanx a lot for the help. im gonna go to radio shack and get some stuff now. guess i’ll go ahead and get that new wire also just in case. im gonna mess around with it and see if i can get a better understanding of how this works.

ok for the daisy chained ground, if i use new wires whats the best way to do it without having to solder? im guessing cut the wire from the joystick thats going to lp and start the daisy chained QD with the new lp wire and old joystick wire from there and use the other new wires from then on? im gonna leave the start and select buttons there since i doubt i need switches for those.

Ensure stronger connection between wire and QD, prevent pullouts trying to remove it from the terminal. They dont solder the QD to the terminal, they solder the wire to the QD. That’s why the solder is only on the back of the QD, and doesn’t connect the QD to the terminal. Check the photos again.

Only the people who don’t have a clue how to crimp solder the wires to the terminals. And those who can crimp don’t use insulated terminals but open barrel type. That gopodular pics shows insulated terminals with the insulation stripped off and wires soldered to them. LOL, if that doesn’t epitomize shitty tech jobs I don’t know what does.

I missed that, good call.

I’m still not seeing anything wrong with crimp and soldering, but looking at the picture, they look soldered and NOT crimped. Weird.

you dont need to solder at ALL

cut the wire coming from the p360(joystick) as close as possible to the lk microswitch as well as the select button also as close as possible to the select microswitch

like this

http://i76.photobucket.com/albums/j24/crateofebola/IMG_0411.jpg

then get those wires and crimp the lp one with a new wire to start the button daisy chain and crimp the select one with a new wire for the start, select daisy chain

then you know daisy chain

Doh. I’m blind.

Good stuff.

As far as that janky ass MAS goes, gut it entirely and rewire. Or send to someone who’s willing to gut then rewire.

Solder only on ours. No crimping.

We use the solder to “seal” the contact surfaces from the air and prevent oxidation. We use those disconnects so there’s a place to grab with pliers without putting any stress on the connection itself. The wire is passed through the tubular portion like a sleeve. With crimping, it’s possible to break the wires right at the crimp point when you jiggle it around to put it on/take it off.

I thought it was a good solution. :wonder:

Back to the thread:

No need to write anything down. Just look at the picture. Then use duct tape or hot glue for the wires. Sometimes scotch tape becomes brittle and just falls off.

A proper open-barrel crimp would be better (my camera sucks):

http://img235.imageshack.us/img235/8954/s2023065gq9.jpg

The only way I would use solder with crimp terminals is to pre-tin the wire (better if quickly dipped into a solder pot), crimp it normally (as shown above) and then heating up the solder so it melts with the terminal. A hard insulation (not softer than UL1007) is necessary to prevent the insulation from melting/retracting thus rendering the insulation crimp weak. But I never do this as I’ve never had a problem with a properly crimped terminal.

i was only able to find fully insulated disconnects. are these ok to use? and could these be soldered to the wires as stated above?

Yeah there fine

well the hole is too small for the wire to fit. im getting tired of this. i might just learn how to solder and deal with it that way.