Thank you Everyone! I greatly appreciate the kind words and your support always makes the efforts worthwhile. I’m glad these have met your approval =).

Was in and out for the day (had to get some rest from lack of sleep getting pics and placing this post), and I come back with so many comments. I will try to address all the questions and as much as I can. I apologize to those I do not personally address, but believe me that all your comments are heart warmingly felt.

Thanks man. The flat pack will meant that I can fit more into a box, but 3lbs overseas is still likely to start off at $30+. However, I can fit a few of these in a Flat Rate for $42 to pretty much any country, so perhaps combining with others may work out better?

Couldn’t have done it without this community =)

Thanks, Markman! A visit from you is a great indicator that I’m going in the right direction =)

Definitely. Just to drive the point I actually stood my entire 155lb weight on one of these. Although I need to take the feets off so the weight was evenly distributed and supported, but it took my weight pretty well. The Border/support structure was designed with sturdiness in mind. I should take a pic of that some time, lol

Thanks! A lot of heart and thought went into it =)

While this first version is designed for JLF/LS-32, I do have plans for a HAPP version if these case runs do well. It will have to be a larger design so it’s gonna be some time on the drawing board first.

As for SE Lamination, I’m still working on it. The guy I’ve been talking to about procuring Lamination stock is being a moron. I’ve told him hundreds of times I need laminate and mounting (adhesive) material that is not vinyl based because laser cutting that stuff is toxic. However, him and/or the vendors he’s talking with are being airheads about it. They sent me samples claiming they are all vinyl free. Well good thing i double checked and googled the material they sent me cuz they were indeed vinyl based and I could’ve damaged my machinery as well as hurt myself had I cut those samples. Needless to say I wasn’t very happy with them. So I’m currently still looking. Sorry for the wait.

Thanks, I will double check the UV reaction ratings for the acrylic I carry and for future stock. However, Acrylic does not yellow over time. It’s polycarbonates that do that =)

Lol, you know… an acrylic recyling unit of some sort isn’t a bad idea. I’d have to look into that. But yeah… uh… garage full of extra acrylic.

Durability is quite good when everything’s put together. As I mentioned above, I can stand on one of these things. However, I will leave the testers to chime in on that when they get their cases =). But vs kids? Eh… what is truly kid proof? I can tell you that dropping it 3 ft to a carpet floor has not damaged my case. But dropping it on a hard floor… yeah, damage is likely unavoidable. It can take a fair amount of beating, imo… but these cases should not be considered something to throw around. But that’s where the ease of replacing a part comes in.

As far as longevity, the top panel is the same concept and thickness as my plexi replacement panels. And I’m still using my Venom replacement panel since I came up with the product. Given that I’ve lent that stick to my friend’s gf on many occasions and it’s still handling quite nicely… really does say something lol. But once you build the stick altogether you will feel just how durable it is. Again, I’ll let others attest to that.

As for weather conditions, the 1/8" thickness is a lot more resistant to warping than the 1/16" material… obviously. But I will still say to try and keep it in average room temperature whenever possible. Like many plastics, they will be affected when exposed to heat for too long. But short of putting these things in an oven, I don’t really have the weather environment to fully test all the possible effects.

Regardless, acrylic products should always be handled with more care. They can’t be compared to it’s wooden or metal counterparts.

Heh, the amount of work put into it… eh, lets say it’s been a non-stop thought in my head for the past 10 months, lol.

[quote=“ViciousXUSMC, post:72, topic:101140”]

Also looking for LS-32 support (hopefully with a nice acrylic mount just like the JLF)

[/Quote]

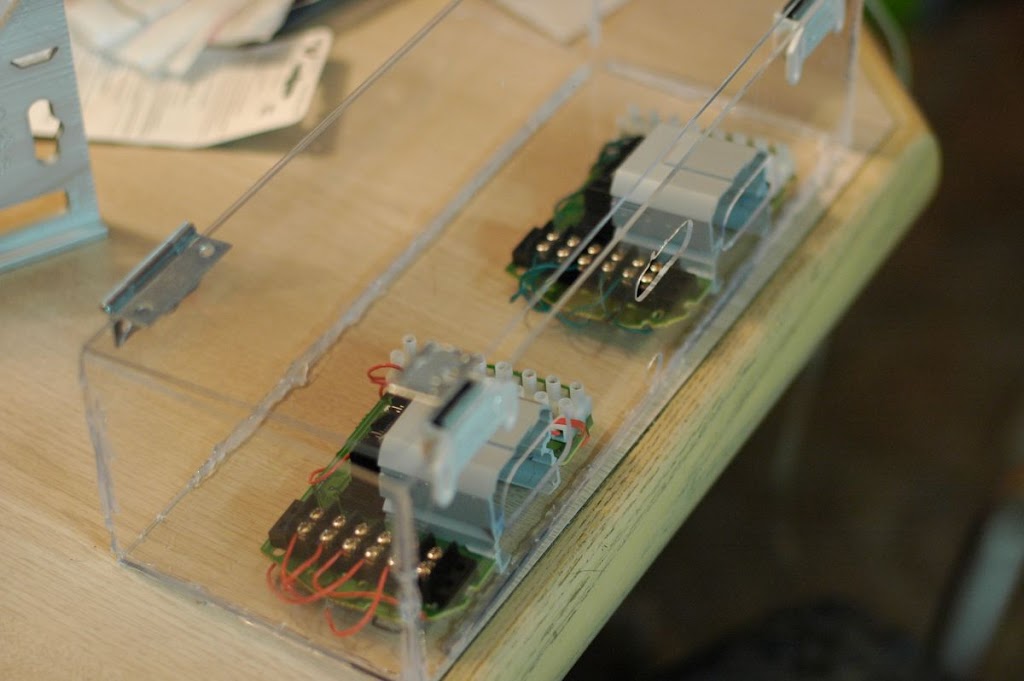

The screw hole positioning for the JLF mount actually fits a LS-32 metal mounting plate. It takes a little more effort for alignment because of the way the corner screw areas are made. I have some pictures of my LS-32 on a panel.

As for plexi mounts for the LS-32, I’ll have to look into it. I would need to know the screw size and threading on the LS-32 to provide the right screws for the plexi since I won’t be counter sinking the mount.

As for the LS-32-01, I will look into it.

Universal Mounting plate… I will have to look into that.

LOL. I doubt you guys know them

Lol, thanks man. Sorry to make you guys wait till after EVO. But because I’m going to EVO and Comic Con, amongst other priorities within the next couple months, it’s difficult to push these out anytime sooner than that. I’d hate to take someone’s money and ask them to wait a month to get their product because I’m not properly setup.

- Yes, holes are pre-tapped.

- 1/4" Acrylic

- In the long run, yes this can be an issue if some care is not taken with repeated screwing. As in, forcing it in too much, using power tools, over screwing, etc. The same precautions I placed on the Plexi Replacement Panels and Top Loaders will be mentioned on these cases. At least with my experience, screwing and unscrewing these cases like mad in all my testing, I haven’t encountered stripping yet. But to prepare for that possibility and to provide customers with a peace of mind, I do plan to include an extra one or two more diamond joints per case. Additionally, they are easy to replace if something unfortunate happens to them and you use up the extra ones.

- The top panel is essentially the same concept behind the Plexi Replacements for the TE and HRAP. Thus far I have had no reports of issues with this thickness being used as a top panel. Furthermore, one of my testers have suggested to me that he feels the overall construction, when everything is put together, is quite sturdy.

- Indeed. This goes back to the same concept as the Plexi Replacement Panels and is in relation to the stress tests I’ve placed upon those. Of the many that I’ve sold, I have not received any negative feedback.

Basically, these cases are the outcome of the positive results from the Plexi Replacement Panels and Top Loaders products =).

Regardless, You will have initial feedback from my testers in the coming weeks and I’d rather you take their word for it.

How can you be done with modding? Never! I will not let you!

These 6 button versions are merely samples. 8 Button version are definitely an option.

I am a bad person =(

All my products are laser cut by my laser cutter. No way I can do this by hand… I would have a stroke, lol.

I’m afraid I won’t have much of an option to increase the weight. Acrylic is relatively light weight and it would take a lot of acrylic to add an extra pound. Well, I guess I can look at possibly adding more 1/4" acrylic blocks… but it could take up a lot of room in the case, and take away from the look. I will keep it in mind though.

Custom side Decors are a possibility, but won’t be an option for a little while. I’ll have to consider if I can set aside time to do that on a custom level, and whether the overall time/cost is worthwhile for people.

Not for this version. I will keep it in mind for future versions.

I’m not exactly sure what the “Standard” is for the home/guide button. But if it’s an extra hole for a 24mm or 30mm button placement, there will be options on adding button holes to the sides of the case. For a glimpse on that, the front panel can support up to Two 24mm button holes on either the far right or far left sides. Or, one 30mm on each side. The left and right side panels can support up to 4 24mm button holes, or 3 30mm button holes .

It’s in the blood =P

Heh, sorry they do not come with cloths. But Microfiber cloths are quite cheap at walmart.

With the current design I can’t say there is really any noticeable flex. Assuming you mean potential flexing when pushing down on the buttons and applying pressure during play. The design of the borders and mid support plates (Name Plate & PCB Plate) addresses this potential issue. My testers can give you their opinions on that. Either case, I will take into consideration on the thicker top/bottom for potentially adding weight. But probably not for the first release.

I can understand the Hinge method, but one thing about that is with a hinge there needs to be a locking mechanism. The concept of this case is to be a simple DIY production. To add a locking mechanism may require addition adhesives or other bonding methods which takes away from the simplicity of the build. Nonetheless, I will take your suggestions into consideration and keep an eye out for a good method to apply everything in a future design.

Would love to see what LED designs you can come up with =)

I need more resources to keep the price down to affordable. I need to be on here a few more months before i can sell anyways

I need more resources to keep the price down to affordable. I need to be on here a few more months before i can sell anyways