You’re going to have to experiment. It’s either the first or the third post, I’m not sure which. I think it’s the first.

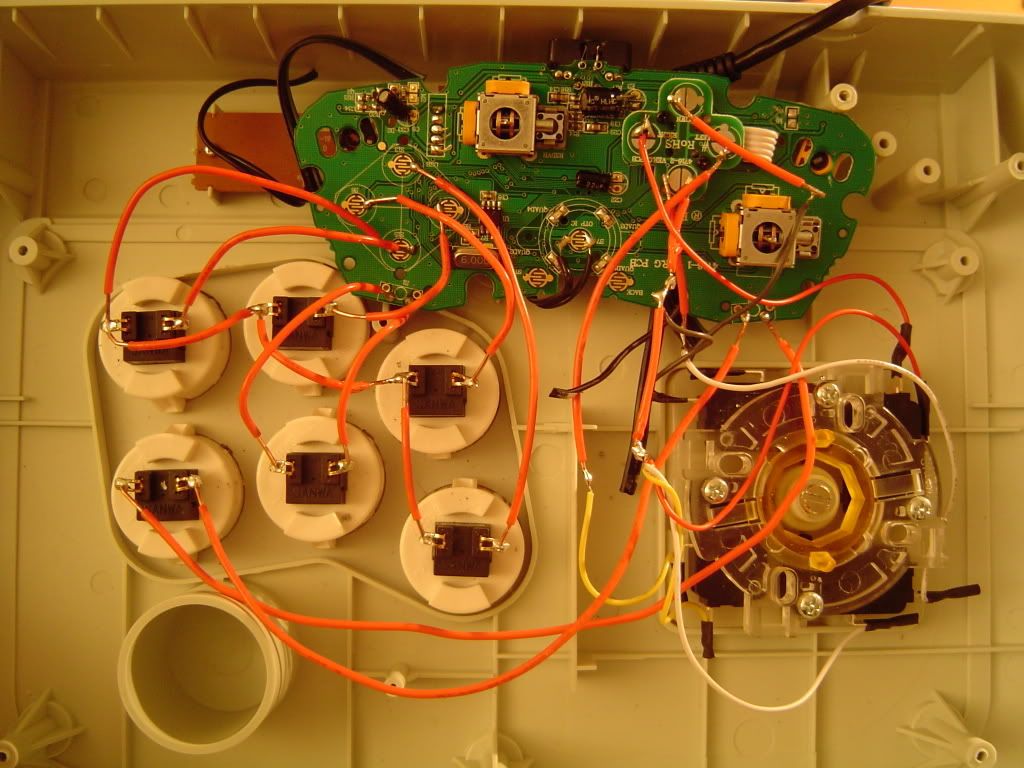

so i’ve been trying to hack this psx series H pcb all day. I only had 26 gauge solid core wire so I used it instead of the usual stranded wire but the wires keep popping off of the PCB. is there some sort of trick to soldering solid core wire? I’ve used solid core wire on other stuff including pads and I’ve never had it pop off on me like this and I’m not doing anything different than I usually do when working with solid core wire. this has me very frustrated. :sad:

The solid wire doesn’t bend easily, which transfers any movement to a force on your solder point. That’s the exact reason why I suggest against using solid wire.

If you’re dead set on using solid, then you need to make your solder joints better. Make sure the copper pad underneath is hot so the solder forms a good bond, and have the wire bent so it lays flat against the copper, giving you more contact between the wire and the pad. Make sure both are hot and try again.

The bad news is that the wire will still resist bending, and if there is too much force and a strong soldering bond, then you risk tearing the pad and trace off of the board. Use stranded.

You can put hot glue over the soldering points once you’ve confirmed they work. That’s what I’ve done with my project, anyway.

Don’t do this.

tutorials i’ve read all did this…is there any particular reason for that comment?

so, I have a new pcb model of the xbox 360 madcatz model 4716 (or w/e the 4 digiits are)

can I assume that the 5v solder point is the one opposite the red wire?, this seems consistent with many other diagrams i’ve seen. but i hate assuming

I’m confused… I’ve got the late version madcatz (rebranded gamestop) as well… and what exactly does a common ground do?

Also, is it ok to take off the rumble motors? Will it cause any problems?

Do I solder each point on my buttons to either side of each button trace on the board? (Circles on either side of each area on the board) Is that the same with the joystick?

Yup. Lots.

#1 Solder, by itself is stronger than hot glue. It’s pretty much like welding two pieces of metal and then adding Elmer’s glue. If there is force enough to break the solder, then there is force enough to pop the hot glue off.

#2 A proper solder bond, which requires very little solder, is STRONG, way stronger that solder by itself and much much much stronger that hot glue will ever be. Unless you’ve been doing it for a while, it can be difficult to appreciate this fact. Soldering is actually a form of welding, and done properly, there is a lot of mixing between both metals and the solder. Make sure your wire AND the pad you’re soldering to get hot, and the bond will be at the molecular level, with the copper and tin and other metals fully intermixed; you’re basically turning it into a single piece of metal.

#3 Let’s say it pops off for whatever reason. Re-soldering the wire to the board becomes a very smelly, smokey, molten glue issue that prevents you from doing even a half assed job of getting it back together. If you’re lucky, the hot glue can be easily pealed off before soldering, but would this be a bad time to point out that it means the hot glue wasn’t stuck to your stuff worth a damn? If you’re not lucky, the hot glue sticks, and won’t come off, making rework always unpleasant, usually difficult and occasionally impossible.

#4 A lot of folks (myself included, back in the day) will feel unsure of their soldering, and want to just solder it ‘good enough’ for everything to remain in contact for the hot glue to ‘seal’ it in. I understand that viewpoint, but have since learned it is wrong. Since the hot glue doesn’t really keep things together (see #1), it’s a false sense of security. The weak soldering will help the wires pop off and the hot glue will do little to stop it. The end result is more difficulty trying to redo it (#3) and more fear and frustration about the entire soldering process, and usually, the brilliant idea of using more hot glue. sigh. If someone instead takes the time to learn how to solder properly so they get a good bond, the entire process gets demystified, the person can see the difference between a good weld versus a bad weld, be confident in their work, and be confident if there ever is any rework needed.

I just finished painting a installing buttons on my first stick and have a quick question before I start with the padhacking. Would it be easiers to just wire up the the LB and RG instead of the LT and RT so you wouldn’t need the extra bits or am I missing something? Thanks.

Yes, you can exclude them if you don’t want to mess with it. ABXY+LB+RB will give you six buttons.

Putting hot glue over solder joints is whack. As Toodles says, good solder joints are quite strong, so if your joints are weak, redo them instead of bandaging them with hot glue. Not sure how strong solder can be? The copper pipes which deliver water to and through your house are connected with solder which is the only stuff holding up against the 60 psi inside, and it doesn’t even break a sweat (pun lol).

I do like to use hot glue near (not on) solder joints to relieve strain on the wires.

Soldering to the direction pads on the 360 controller

Can anyone that’s successfully soldered to the tiny points for the direction buttons on the 1st party 360 pad please share their technique?

I have the newer common ground wireless pad (thank fuck) and have carefully revealed the copper pads, but took one look at it and almost cried. The large points for the face buttons were stressful enough! I’ve tried practising on a ground point of the same type and can’t work out a good method.

Here’s the technique I’ve had the best luck with…

Firstly, using thin stranded wire (no idea what gauge) I take only two strands and tin it. My solder is Ersin flux Savbit alloy 18 SWG, contrains lead (this shizzle). I have thinner solder with silver, but read that it doesn’t flow so well.

I try to lay the tinned wire just next to the copper pad so it’s nice and steady.

Using a thin point iron set to 450-520F (260C) I heat the wire, stroking it with the iron so the solder beads at the end, where the copper pad is.

One out of many tries on my practice point it worked. Didn’t work on the signal pad so gave up for today.

Seems it just doesn’t want to stick at all. What’s the secret, pad hackers? Spit? bear grease? 20-20 vision? Diazepam?

same here

p.s. also I have a third party wired PS3 stick. The d-pad and left thumbstick show up as one as the same in windows game controllers. iow moving the d-pad left is the same as moving the left thumbstick.

Is this good or bad for pad hacking the d-pad? Any issues with fighting games? The d-pad doesn’t go through all the variable degrees of direction as the left thumbstick of course.

@Skonig:

No common ground here.

What kind of soldiering flux do you use? You’ve put some soldier before to the pad?

Oh, fine. Never heard of this ones. Could you give me link?

I’ve only ever used the flux that is in the cores of my solder. Never used it separately. The solder I’m using has ‘Ersin’ flux. I’ve soldered to tiny micro processor legs before, but this is proving more difficult.

My PCB is the common ground wireless version. Slagcoin’s diagram.

Failing that… how about soldering to the vias traced out on RDC’s diagrams… or failing that… lifting the IC legs. :S

What method should be most straight forward?

I’m using additional flux like this for fine grained task:

http://www.farnell.com/datasheets/102305.pdf

However when you’re thinking of soldiering directly to the IC pins what about finding some better soldier points with a multimeter? This is the way I proceed. I don’t like to soldier on this black buttons pads. It’s easier to remove soldier resists than scraping this black stuff away.

I know its not the best solder job… but its the best I can manage… however I’ve got a problem?

I screwed on the backplate for my EX2… and now when I run SFII:THD my character is crouched and I can’t move? I can still press all my buttons… I do occasionally jump if I keep pushing the stick, but its once every 25 or so pushes (not a standard number).

What happened? I assumed it was the analog sticks… since I haven’t taken them off, but they don’t even seem to function anymore… is there a problem with that? I haven’t desoldered anything from the analog stick area…

It was working fine before I tried screwing on the back plate…

EDIT:

The stick works fine when I’m not in SF… I can navigate the tabs fine, although even in the dashboard the analog stick doesn’t function (I’m not sure if it did before… I never tried to test it)

Thanks for the reply, but I’m actually using a PS1 PCB which I believe doesn’t have any pressure-sensitivity.

My problem is the 360 triggers, even with a 10k resistor attached, are some form of ‘ground’. All I need is someway to get rid of that ground and it’d all be gravy. I’m just completely clueless in how to go about doing so. :sad:

Thanks for taking the time though.

I’m no pro, (as you can see I’m having my own problems) but the back plate is metal’ish of some sort…did you cover it with electrical tape or anything?

If it’s not that, then I’d guess the 360 triggers since I see you still have the black spinners on. If they’re not in a specific angle they’ll activate :db: on the analogs, so that could also explain why your analog sticks aren’t working.